Stribet | Winter 2024

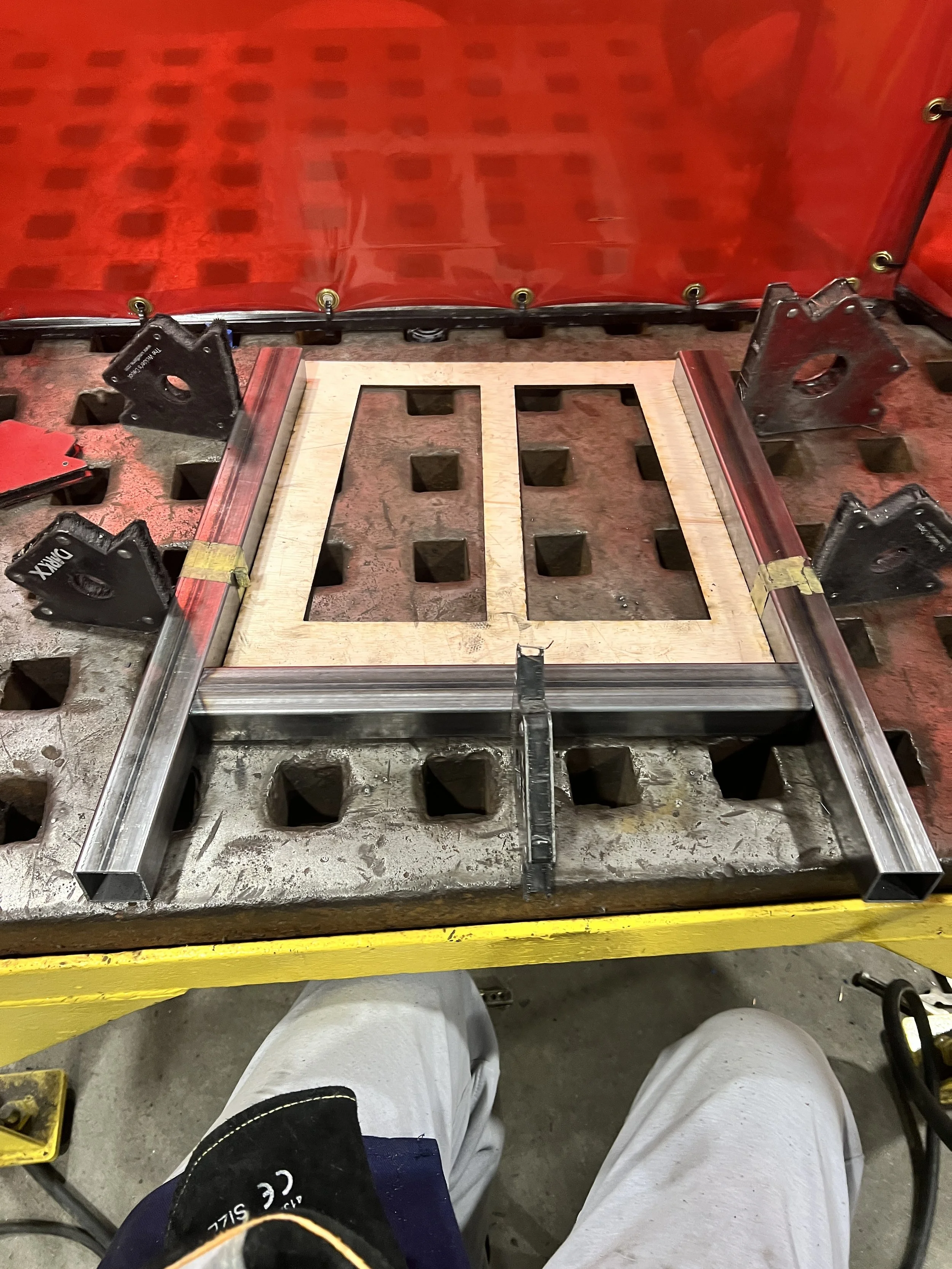

In my Advanced Model Building course, I fabricated a stool titled Stribet entirely from a provided CAD file, without modifying the design. I built the contoured zebra wood seat using a custom router jig and constructed the steel frame with self-made welding jigs, completing the project with high precision despite a shop injury with my finger.